Indistylemen

Shell Cordovan Leather Explained

- Get link

- X

- Other Apps

Shell Cordovan is a staple material of fine men’s shoemaking, but you may wonder what makes this kind of horse (!) leather so special that it commands $500 or more per pair of shoes.

From the outside, shell cordovan looks quite similar to any other shoe leather – smooth, lustrous, and richly colored in shades of burgundy, brown, and black – but it has some unique properties that make it ideal for men’s shoes. It’s also a far rarer and more labor-intensive leather than cowhide. Let’s investigate what shell cordovan is, its history, how it is created and how to find, buy, and care for shell cordovan once it’s part of your collection.

Open cuffs, Fort Belvedere shadow stripe socks & Meermin shell cordovan tassel loafers

What is Shell Cordovan?

Shell cordovan is the name for a leather derived from the hindquarters of a horsehide. It’s one of the few types of leather that consumers might know by name.

The “shell” refers to the hindquarter part of the hide once it has been split horizontally to remove the grain. The name “cordovan” derives from the city of Cordoba, and means “from Cordoba”; together the terms refer to this specific type of horse leather.

Shell cordovan comes from only a small part of the horsehide

Unlike other leather, the shell is a membrane in the middle of two epidermis layers in the rear portion of a horse butt. The hindquarter portion of the hide used for shell cordovan begins at about 24″ from the tail and extending 24-28″ on either side of the horse. The exact size depends on the particular horse.

Characteristics

Shell cordovan is exceptionally durable. The pores are so dense on the hindquarters of a horse that they are not visible to the naked eye. The hide is naturally resistant to water (though not impervious) as well as stretching. Instead of creasing, shell cordovan ripples.

Cordovan ripples as opposed to creasing

Since creasing can lead to cracks in the leather, the tendency to ripple rather than crease helps to preserve the surface of the leather and the overall lifespan of the shoe. Furthermore, shell cordovan ages very well and develops a particularly beautiful patina over time. A well cared for pair of shoes can truly last you a lifetime.

Dalton boots from Allen Edmonds in shell cordovan with Off White Fort Belvedere Boot Laces

The leather itself doesn’t accept dye very well so it’s mostly found in dark shades of brown, black and what is known as “cordovan” color, which is a dark burgundy rose color. It takes approximately 1 and a half shells to make a pair of shoes.

Why is shell cordovan so expensive?

The high price of cordovan comes down to the low supply of hides, the high demand for them, and the long, complicated tanning process. Since horses are only raised as part of the food chain in a few places in the world, the supply of horsehides is small and unlikely to grow, contributing directly to the scarcity and high price of this type of leather. Only a small portion of the horsehide can be used and it can’t be split into layers like cow leather. Tanning alone takes 6 months and a great deal of handwork; very few tanners have the knowledge to tan it.

Smearing the Cordovan Butts

Shell cordovan is a truly rare and unique material, and prices vary, though it tends to hover around $100 per square foot. The cost is warranted considering the factors surrounding its production.

History of Shell Cordovan

Leather has been produced and used by man since 2200 BC, but the first documented use of horse leather was in 7th century Spain by the Visigoths and eventually by the Moors.

The city of Cordoba, from which shell cordovan derived its name, was a noted center for leather tanning.

Traditional Cordovan Leather from Cordoba, Spain

In the 16th and 17th centuries, skilled craftsmen would create preciously decorated horse leathergoods such as wall hangings, trunks, shields, and armor.

Meryan in Cordoba

Even today, you can find artisans such as Meryan in Cordoba who still maintain the tradition of Cordovan leather (sometimes also referred to as Cordoban). Because of its qualities, beauty, and durability, it found its way to the Spanish Royalty, who facilitated the spread of cordovan leather throughout Europe and the world through marriage with other royal families.

It wasn’t until the 19th century that shell cordovan was connected with the specific type of tanned horsehide that is used today.

Hides piled up outside the tannery

In the middle of the century, German and Dutch tanners arrived in the US with their trade for “spiegelwahre”, which translates to “mirror ware”. The name is a reference to the fact that polished cordovan achieves a mirror-like finish. Their profession became known as “Cordwainers”.

Shell cordovan is noted for a natural high glass shine, hence the term “mirror ware”

That being said, shell cordovan in the 19th century was a thick, tough leather prized more for its durable nature than for its good looks. It was commonly used for leather razor strops until the safety razor emerged around WWI and the industry had to pivot to a new product. In the early 20th century, American tanners further improved the tanning techniques to make shell cordovan softer and more appropriate for shoes.

Vintage Wolverine shell cordovan boot ad

In 1910, Wolverine advertised its shell cordovan boots and gloves as being “buckskin-soft.”

Shell Cordovan Today

Today, only a few factories in the world tan shell cordovan. Among them, the most recognized is Horween, which is based in Chicago.

Horween Leather Company Chicago

Style-wise, shell cordovan today walks the line between casual and dressy; casual due to its history as a workwear material and, on the opposite side, dressy due to it’s higher price and rarity. Most brands use shell cordovan for shoes such as tassel loafers, bluchers, wing tips and a variety of boots.

Cordovan Production

The tanning of cordovan is incredibly complex. Six months and more than a hundred processes are required to produce a useable hide, and therefore, very few tanneries remain in the world still produce this kind of leather. At Horween, although roughly 80% of their business stems from tanning cowhides, they are probably most famous for their genuine Shell Cordovan leather.

Salted Horsehides

Tanning is a process that does two basic things: it stops the natural decay process and develops the desired characteristics of the leather. It starts out with salted horse hides. They are sourced from France, despite the common belief that Horween leather is an entirely American product. For more on the subject, read our article about Made in the USA.

The horsehides arrive on pallets and are then cut down by hand. Only the butt portion of the hide is tanned as shell cordovan.

Horween tanning pits

In order to remove the hair, they undergo some chemical treatments described in the tanning process; they are then tanned in pits using Horween’s proprietary tanning solution which consists of chestnut and quebracho tree bark as well as resins.

The horsehides are put into frames that agitate constantly. This ensures that the tannins don’t settle and the hides are evenly tanned.

After thirty days, the horsehides are taken out of the solution and then shaved to expose the shell. Subsequently, it is put into another pit with a stronger solution and tanned for another 30 days.

The two tanning stages cannot be rushed, or the outside skin fibers would only be penetrated by the tannins, while the inside would be still raw.

Finished shell cordovan in a range of colors

Once the tanning process is complete, the hides still require another 4 months of work before they become finished leather. The hides are polished and colored by hand, and most importantly, they have to rest.

Horween sometimes has to turn customers down due to lack of supply. When these customers then see the piles of shell cordovan in the factory, they don’t always understand that the shells have to rest.

In order to better understand the whole tanning process, check out the following video which shows the different steps of the cordovan production.

How to Buy Shell Cordovan

The first step is to decide if shell cordovan is the right material for you to buy because it is a significant investment. Personally, I am not a huge fan of shell cordovan shoes because they wrinkle in a certain way, are harder and less breathable. However, I know quite a few people who swear by it. My advice is to check it out yourself – chances are you will either love or hate it. New shoes will feel stiff, but take a trip to the vintage store, and look for the trademark ripples and color of cordovan to try out what a pair of broken-in cordovan feels like for yourself.

Cordovan structure

Shell cordovan is a great addition to your shoe closet if you appreciate the unique look, feel and durability of the leather. It is especially great for enthusiasts that want a hard wearing, casual-to-informal shoe that they plan to care for and re-sole for many years to come.

Shell cordovan restoration; note the deepening burgundy color

You’ll mostly find shell cordovan in shades of brown and black, and of course “cordovan” burgundy. However, this classification can be misleading because cordovan leather has its very own way of achieving a certain kind patina through exposure to sunlight.

Shell cordovan typically comes in a small range of colors

Over time, “cordovan” ages from a burgundy tinged brown color to reveal a bit more of the red tone with each passing year. Other shell cordovan colors will also age and darken, with the exception of the black.

Shell Cordovan Shoemakers

Considering the rarity of shell cordovan, it’s not always available and well-marketed shoe releases often sell out quickly. Brands that consistently sell shell cordovan over multiple shoe models include Alden, Allen Edmonds, Viberg, Carmina, and Rancourt, among others.

Viberg’s Color 8 Work Boot in Shell Cordovan

Expect to find classic, informal shoes such as tassel and penny loafers, and work-boot inspired styles of all kinds. It’s not an ideal material for elegant, sophisticated looks, but for elevated casual and every day looks cordovan is an excellent choice. Considering the cost of the leather itself, makers of cordovan shoes tend not to cut corners when it comes to construction.

Alden shell cordovan tassel loafer

Given the sturdiness of shell cordovan, you can buy either new or vintage with confidence. Just note the return policy of the retailer, in case you don’t happen to like the feel of the shoe.

How to Clean and Polish Cordovan

Cordovan is different than other leathers and as such, many claim the treatment is different. In my opinion, you should use an emulsion shoe polish and rub it into the leather in concentric circles with either a brush or a piece of cloth. Some also claim that a shoe bone should be used. Unlike most shoe horns, this bone is actually a hind (leg) bone of a deer.

Deer Shoe Bone

Apparently, it is used for cordovan because it has the right amount of oil to ensure the surface is not damaged without over saturating it. In my personal experience, the outcome with or without a shoe bone was the same. As you will soon find out, there are many ways to polish shoes and everybody has a little secret.

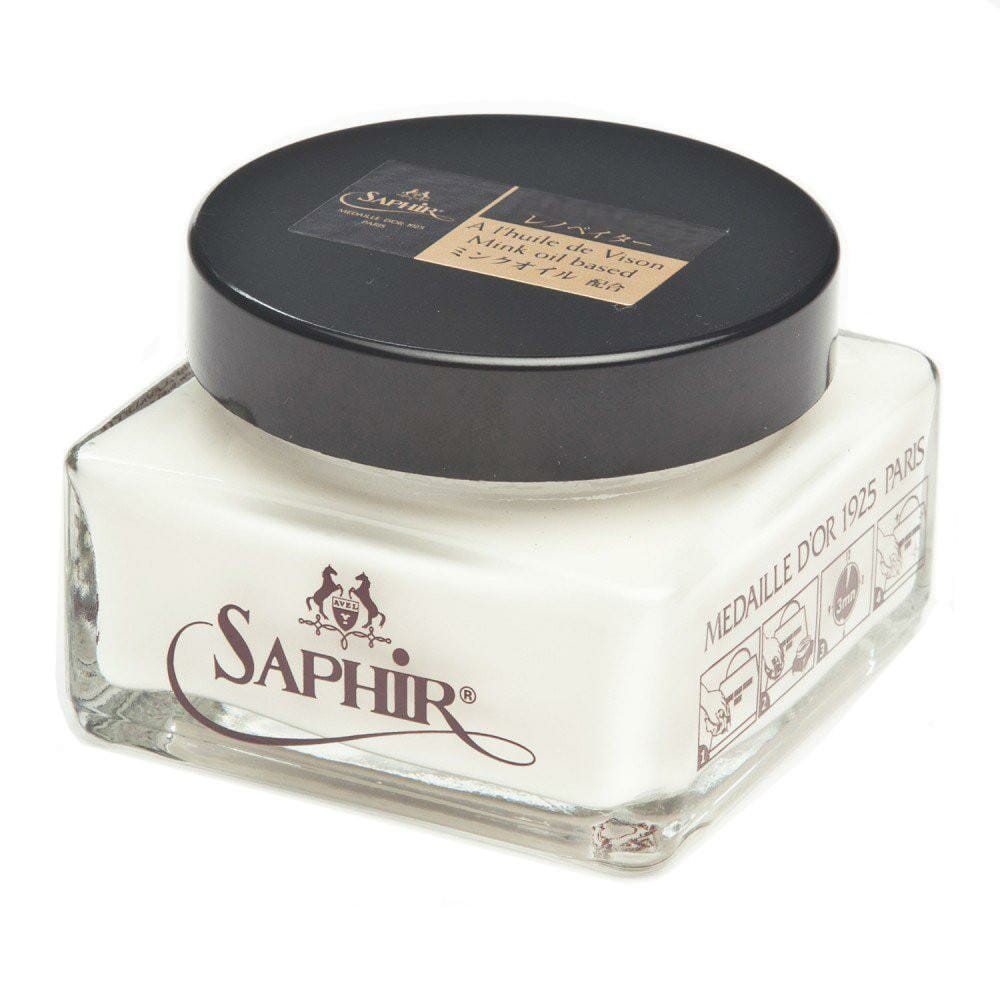

Saphir Cordovan Polish

With regards to shoe polish, Saphir now has a cordovan shoe polish in their portfolio but a regular emulsion cream (not turpentine wax) paste will do just fine as well. Since Cordovan is a very rough leather, you do not have to worry about it and if you go to the lengths of using emulsion shoe polish and a brush, you are ahead of most people out there.

Shell Cordovan before and after Saphir cordovan polish

Conclusion

Shell cordovan’s special qualities aren’t for every person’s closet or budget, but they are a cornerstone of classic men’s footwear. What shell cordovan shoes and accessories do you own?

from Gentleman's Gazette https://ift.tt/2DT2XhF

- Get link

- X

- Other Apps

Comments

Post a Comment

thanks for your feedback